The hospital is faced with the handling of thousands of pieces of work clothes, clothes handover, washing, ironing, finishing, storage and other processes every year. How to effectively track and manage the washing process, washing times, inventory status and effectiveness of each piece of clothing Classification and so on is a great challenge.

1. Handover of washing tasks on paper, complicated procedures and difficult inquiries;

2. Worry about cross-infection, leading to the inability to carry out statistics on the quantity of certain laundry items;

3. The washed quantity does not match the task;

4. Every step of the washing process cannot be accurately monitored, and the clothes are missing the treatment link;

5. The washed clothes are classified accurately to save storage space;

6. It is impossible to accurately arrange the minimum safe inventory of each piece of clothing.

The introduction of RFID technology will make the hospital's laundry management more transparent, improve work efficiency, and solve management problems that could not be achieved by other technologies in the past, such as: large quantities of laundry statistics and handover.

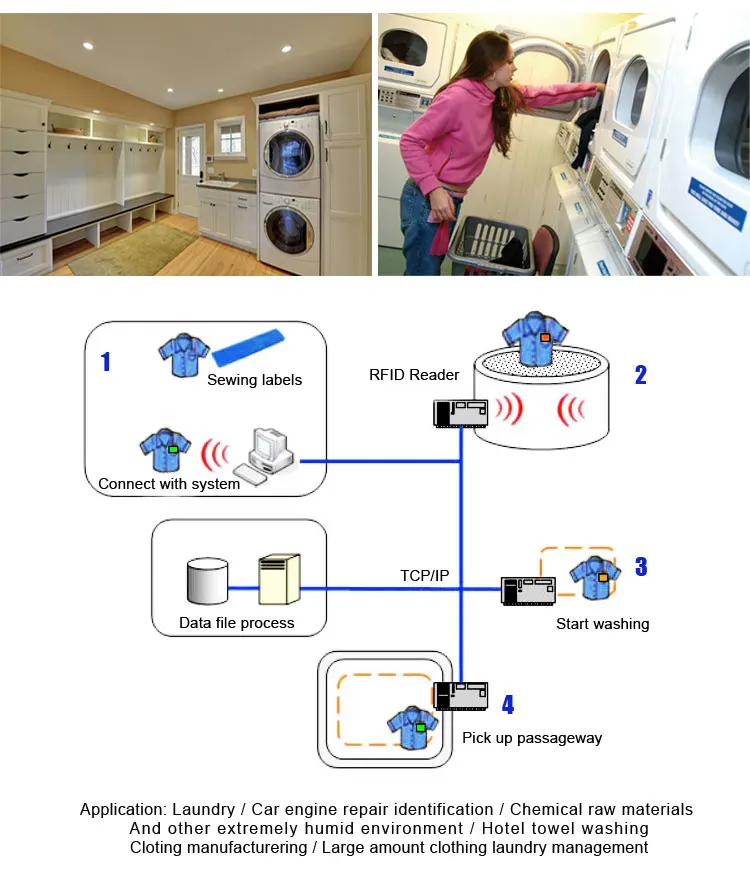

RFID linen washing management principle

Sewing RFID electronic tags on each piece of clothing, the electronic tag has a globally unique identification code, that is, each piece of clothing will have a unique management identifier until the clothing is scrapped (the tag can be reused, but it does not exceed the life of the tag itself) . In the entire clothes usage and washing management, the RFID reader will automatically record the clothes usage status and washing times. It supports batch reading of labels during washing handover, making the handover of washing tasks simple and transparent, and reducing labor costs. At the same time, by tracking the number of washings, the hospital can estimate the service life of the current clothes and provide forecast data for the procurement plan.

RFID linen washing business process

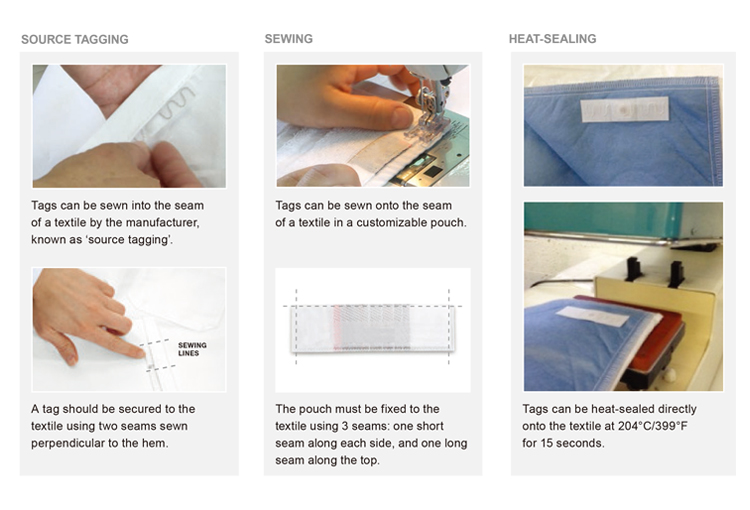

01. Linen data entry, RFID tags are sewn into clothing

The chip in the tag can store data, associate the attributes of each laundry to be managed and the RFID tag ID in the database, record and track the workflow and life cycle of each laundry, and sew directly on the laundry to be managed. The location is easy to find.

02, linen data collection and reading

Linen stitched with RFID tags are directly packaged. The quantity is automatically collected through RFID reading and writing equipment, and the ID of each piece of linen read is recorded. Since the data is not counted manually, it improves work efficiency on the one hand and brings convenience to the management side.

Data collection in the receiving and sorting area of the workshop warehouse

Weigh the cart and read the information

Washing clothes in the laundry workshop

03. Inventory of linen quantity

The number of hospital staff can be quickly handed over by configuring handheld devices when handing over.

The hospital staff counts the number of clean linen

Advantages of RFID linen washing

1. Labor can be reduced by 40-50%;

2. The visualization of more than 99% clothing products reduces the risk of missing clothing;

3. Improved supply chain management will reduce work service time by 20-25%;

4. Improve the accuracy and reliability of stored information;

5. Efficient and accurate data collection to provide operational efficiency;

6. Automatic collection of data for distribution, recovery and transfer, reducing human error;

7. Reduce the overall cost of laundry management in hospitals.

Application