What are the advantages of RFID technology for the management of fire-fighting equipment?

Improve the timeliness and accuracy of system ERP data:

Many aspects of traditional management use manual registration, which is easy to make mistakes; due to manual failure to register in time, the data in the ERP system is not accurate enough.

Real-time monitoring of controlled assets:

Manage the life cycle of materials and track the use status of equipment.

Automatically collect data to improve work efficiency:

Automatic data collection in the process of entering and exiting the warehouse, improving work efficiency.

Provide basis for decision analysis:

The data can be analyzed online or generate reports for leaders to make decisions and analyze.

RFID radio frequency identification is a non-contact automatic identification technology, which automatically recognizes the target object and obtains related data through radio frequency signals. The identification work does not require manual intervention and can work in various harsh environments. UHF RFID technology has the characteristics of rapid identification of multiple tags, anti-pollution, durability, large data capacity, safety and diversity. These features make the management of fire-fighting equipment more efficient and simple.

The storage of traditional fire-fighting equipment and facilities requires a lot of manpower and material resources, and the work efficiency is relatively low. The application of RFID technology has greatly improved many problems. Before the equipment is put into storage, the corresponding RFID electronic tags should be placed on the fire-fighting equipment according to the category, and the corresponding asset information should be bound in the background. After the passive RFID electronic tags are affixed to all fire-fighting equipment within the jurisdiction, the entry and exit of the warehouse can be intelligent, automated, and informatized.

Inspection QR code

Based on the code scanning function of the mobile terminal APP, the static QR code is bound to the inspection facility as a quick entry for the static information and dynamic status of the equipment. Through the associated inspection standard system, the inspection facilities are automatically reminded of precautions.

Inspection plan

It can support different time periods, such as daily, weekly, or monthly, and other flexible inspection plans, and automatically generate inspection tasks.

Inspection record

Real-time statistics grasp and record the completion of inspection tasks, support long-term data storage and backup, provide traceability of historical inspections, support export inspection records, and provide inspection managers with a scientific and accurate assessment basis.

The fire-fighting equipment inspection system uses the Internet of Things, big data and cloud computing technologies to determine the safety management responsibilities of the location entities. The system adopts a forced fire management model to improve the traditional fire safety inspections of the unit and the current status of untrue inspection records, solve the problems of unit inspectors "will not check" and "unwilling to check", and realize fire protection wisdom Management.

We are able to support kinds size hard or soft ,UHF RFID on Metal tags,Here is for hard metal tags

And our metal tags had excellent working in many projects, such as :

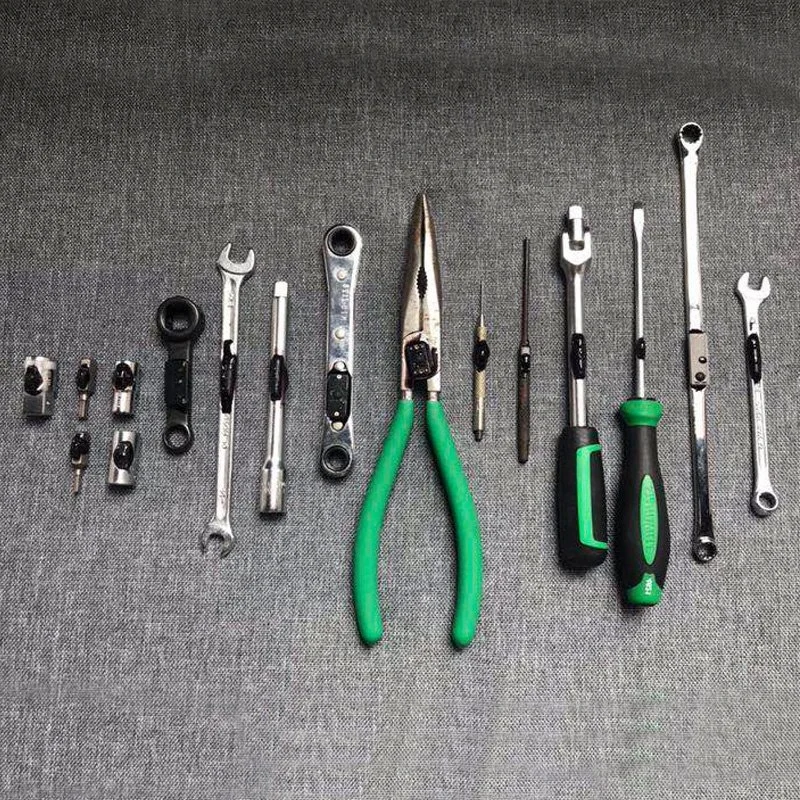

Tools Inventory