UHF RFID technology has transformed the way businesses track and manage their assets, especially in environments where metal surfaces are prevalent. Our UHF RFID Anti-Metal Tags are at the forefront of this innovation, offering unparalleled performance and versatility. In this article, we will delve into the details, features, applications, and advantages of UHF RFID anti-metal tags.

Understanding UHF RFID Anti-Metal Tags

UHF (Ultra-High Frequency) RFID anti-metal tags are specialized RFID labels designed to overcome the challenge of metal interference that conventional RFID tags face. These tags are built with a unique shielding layer to ensure optimal performance when attached to or near metal surfaces, providing reliable and accurate identification.

Key Features and Benefits

- Enhanced Read Range:

Our UHF RFID anti-metal tags utilize advanced antenna designs and optimized frequencies, enabling an extended read range even in the presence of metal objects, maximizing operational efficiency and accuracy.

- Durability and Reliability:

Crafted with rugged materials, these tags are resistant to harsh environmental conditions, such as moisture, temperature variations, and UV exposure, ensuring long-lasting performance in demanding applications.

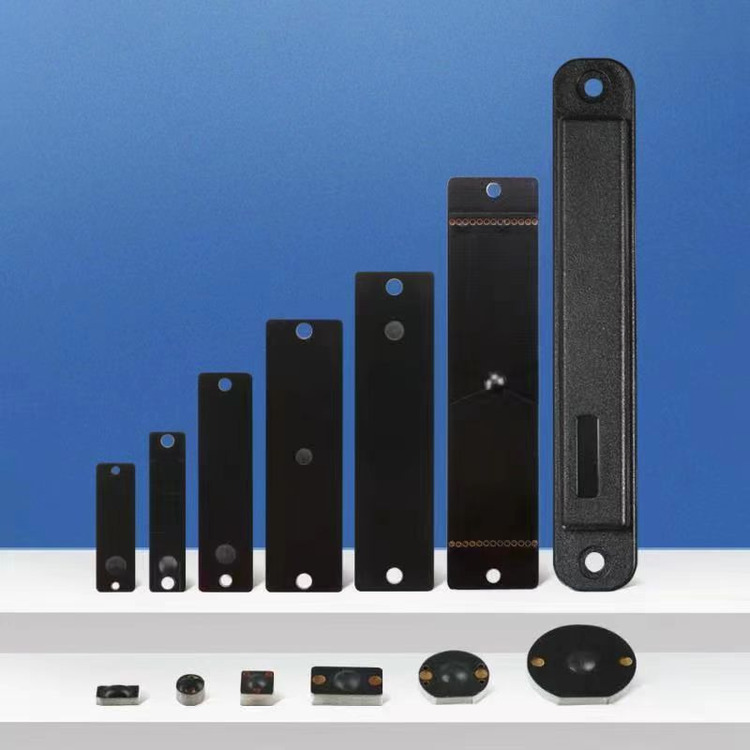

- Versatile Form Factors:

Our company offers a wide range of options in terms of sizes, shapes, and attachment mechanisms, ensuring seamless integration into various asset management, inventory tracking, and supply chain applications.

- Customization Capabilities:

With our state-of-the-art manufacturing facilities, we can customize the UHF RFID anti-metal tags with logos, QR codes, barcodes, and text, enabling effective branding and identification solutions for our esteemed clients.

Applications

- Asset Tracking and Management:

From industrial equipment and machinery to IT assets and containers, UHF RFID anti-metal tags facilitate accurate tracking, inventory management, and maintenance scheduling, ensuring optimal asset utilization and cost savings.

- Manufacturing and Supply Chain:

These tags play a crucial role in streamlining production processes, inventory management, and logistics tracking, enhancing traceability, minimizing errors, and improving overall operational efficiency.

- Oil and Gas Industry:

In this challenging environment, UHF RFID anti-metal tags provide reliable identification and monitoring of pipelines, tools, and equipment, ensuring safety compliance and minimizing downtime.

- Automotive and Aerospace:

With their ability to withstand extreme conditions and metal-rich environments, these tags are widely used for tracking parts, components, and maintenance history, optimizing workflows and reducing manual errors.

In summary, our UHF RFID Anti-Metal Tags are revolutionizing asset management in the presence of metal surfaces. With their robust construction, extended read range, and superior anti-interference capabilities, these tags offer unmatched performance in challenging environments. Our commitment to customization ensures that our tags meet the unique requirements of each client, while our dedication to quality ensures reliable and accurate results. Contact us today to discover how we can assist you in streamlining your operations, enhancing efficiency, and maximizing your return on investment.